Ruggedly constructed fans designed and manufactured to endure severe operating conditions. Fans are capable of developing differential pressures of 125” Wg (4.5 PsiG) per casing and flows to 125,000 CFM. Units are available in nominal, gas tight and absolute zero leakage construction with a variety of metallurgies suitable for handling corrosive gases, as well as wide temperature extremes ranging from low cryogenic to as high as 1,100° F.

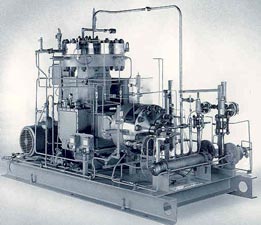

Non-contaminating, process air and gas, diaphragm compressors with compression ratios as high as 15:1 per stage. Ideally suited for applications handling rare or toxic gases where positively no leakage or contamination is essential. Head Integrity Detection Systems monitors diaphragm group and process seal. Complete skid mounted systems are available with flows from less than 1 to more than 150 inlet CFM and with discharge pressure to 30,000 PsiG.

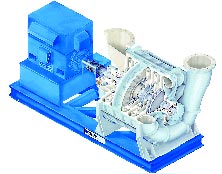

Multi-Stage centrifugal blowers for air or gas handling applications. Driven through either the inlet or outlet side, units are rated for flows as high as 41,000 CFM and pressures from a few inches of water gauge to 25 PsiG per casing or vacuums of 1” to over 15” Hg. The blowers are inherently oil free in design and are available with shaft seal options suitable for inert, combustible, toxic or corrosive gases with inlet temperatures from 0 to 200° F.

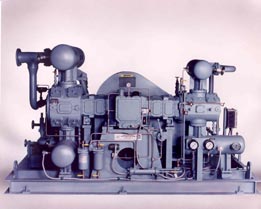

Single and multi-stage, water-cooled, process, piston compressors built to comply with industry standards and/or API-618 specification. Non-lubricated, mini-lubricated and lubricated cylinder construction is available with metallurgies suitable for handling toxic, corrosive, rare and hard-to-handle gases. Frame sizes to 1,760 HP with flows from 10 to 6,000 inlet CFM and operating pressures to 3,700 PsiG. Available as skid mounted, packaged assemblies with ancillary components.

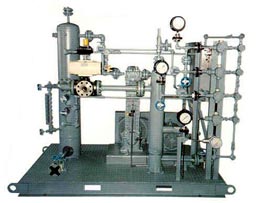

Air cooled, single and two stage, non-lubricated “Dry Cylinder” type, process air and gas, piston compressors. Flow rates range from 2 to 100 inlet CFM with discharge pressure to 600 PsiG. Typical applications include vapor recovery, liquid gas transfer, tank car unloading, pilot plant processes, oil-free instrument air and differential liquid transfer. Standard low cost packages available including suction liquid traps and instrumentation components.